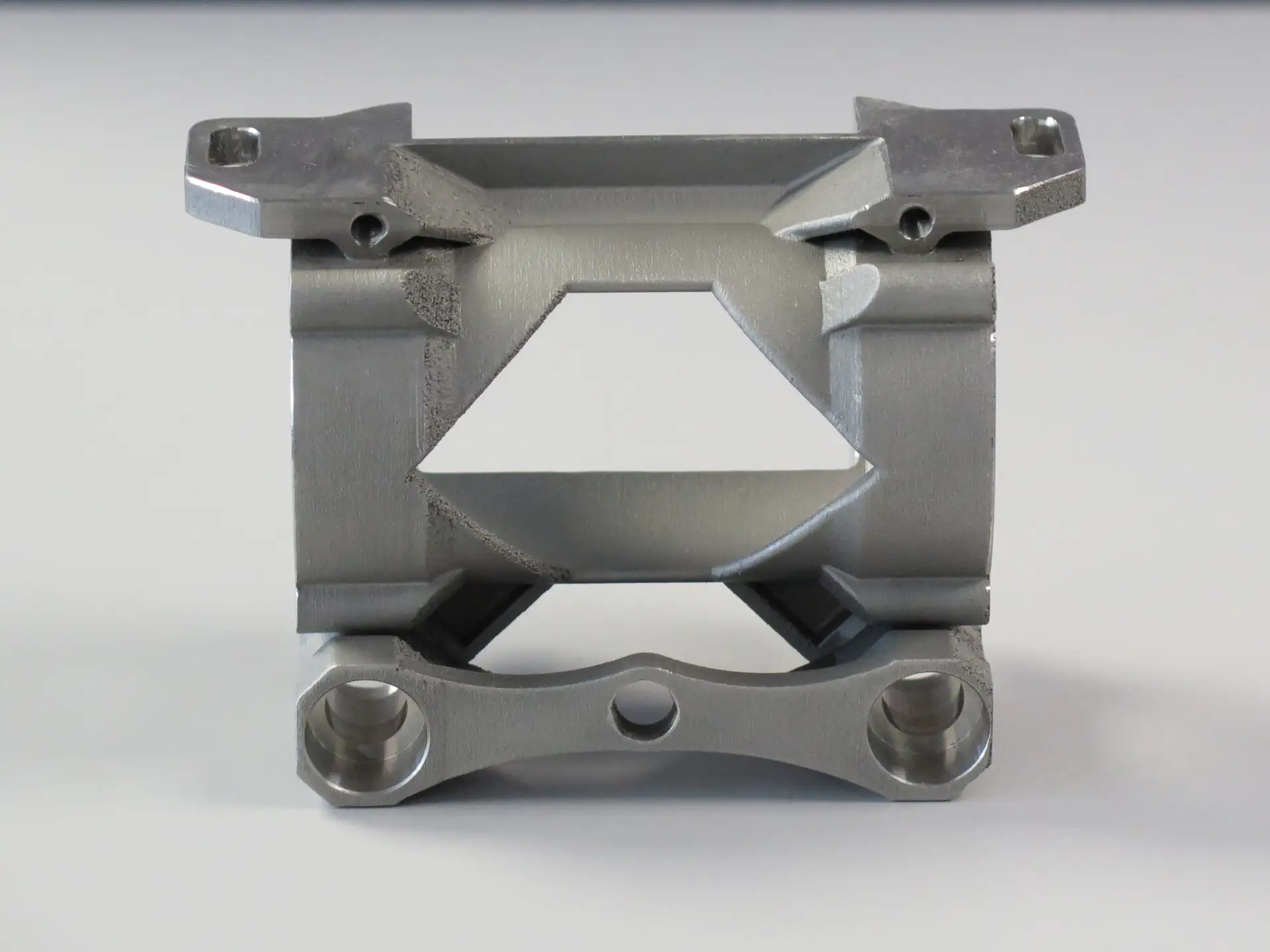

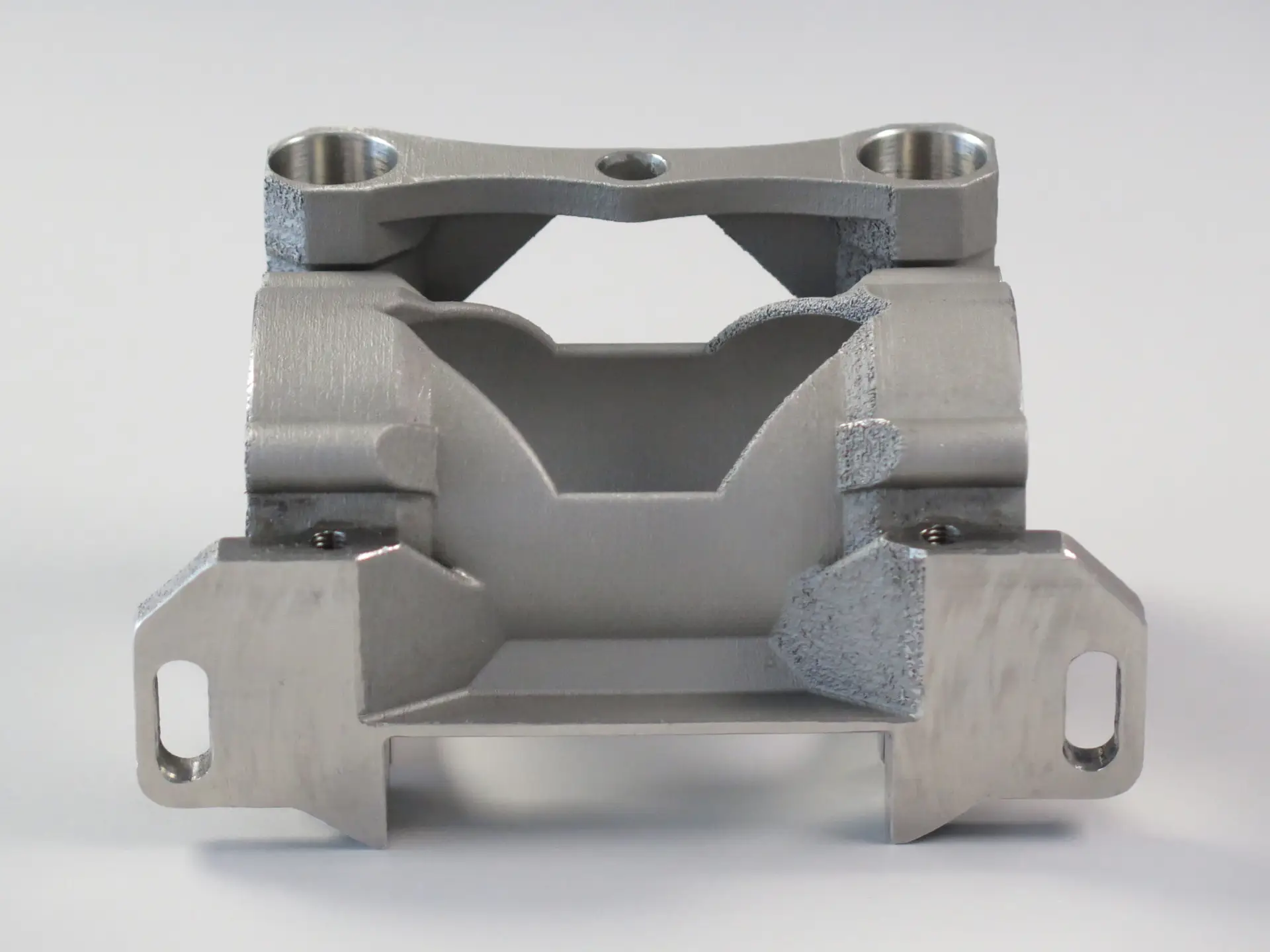

Raute identified certain wood processing equipment components that were traditionally CNC machined but had high complexity and significant production costs. The company saw Laser Powder Bed Fusion (LPBF) additive manufacturing as a way to produce these parts faster, simpler, and more cost-efficiently.

Collaborative design sessions were held to explore design possibilities, understand the LPBF process effects, assess pricing, and capture key learnings.

The parts were then manufactured, documented, and shipped by the AM Campus operators. Testing confirmed that large-quantity production could achieve significant cost savings — with handle parts priced at just €60 each when printed in batches of 30–40 units.

The project demonstrated how metal additive manufacturing can replace complex CNC machining for certain parts, reducing both lead time and unit cost while simplifying production workflows.

Learn more about additive manufacturing possibilities at FAME ecosystem. Join us to collaborate on next-generation manufacturing solutions and accelerate innovation at the AM Campus: contact fame@dimecc.com.